►Know how

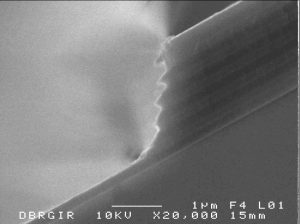

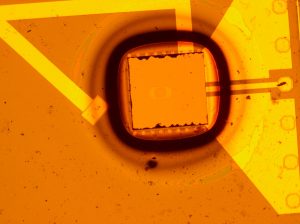

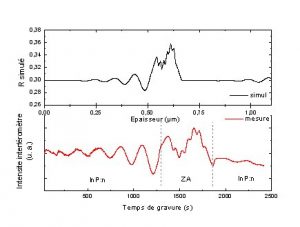

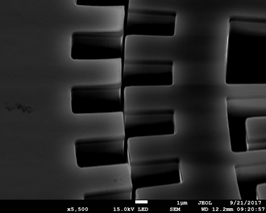

The Nano-Rennes platform can etch a whole range of materials either by wet and/or dry etching. Dry etching are made in dedicated reactive ion etching reactors (RIE). Wet etching are performed under dedicated chemical hood.

The platform has know-how in processing the following materials:

- Si-based materials (Si, Si3N4, SiO2, Ge, SiGe, …)

- InP-based materials (InAs, InGaAs, InAlAs, InGaAsP, InAlGaAs)

- Polymers (photoresist, BCB, …) and metals (In, Au, Ti, Ge, …)

►Etching facilities

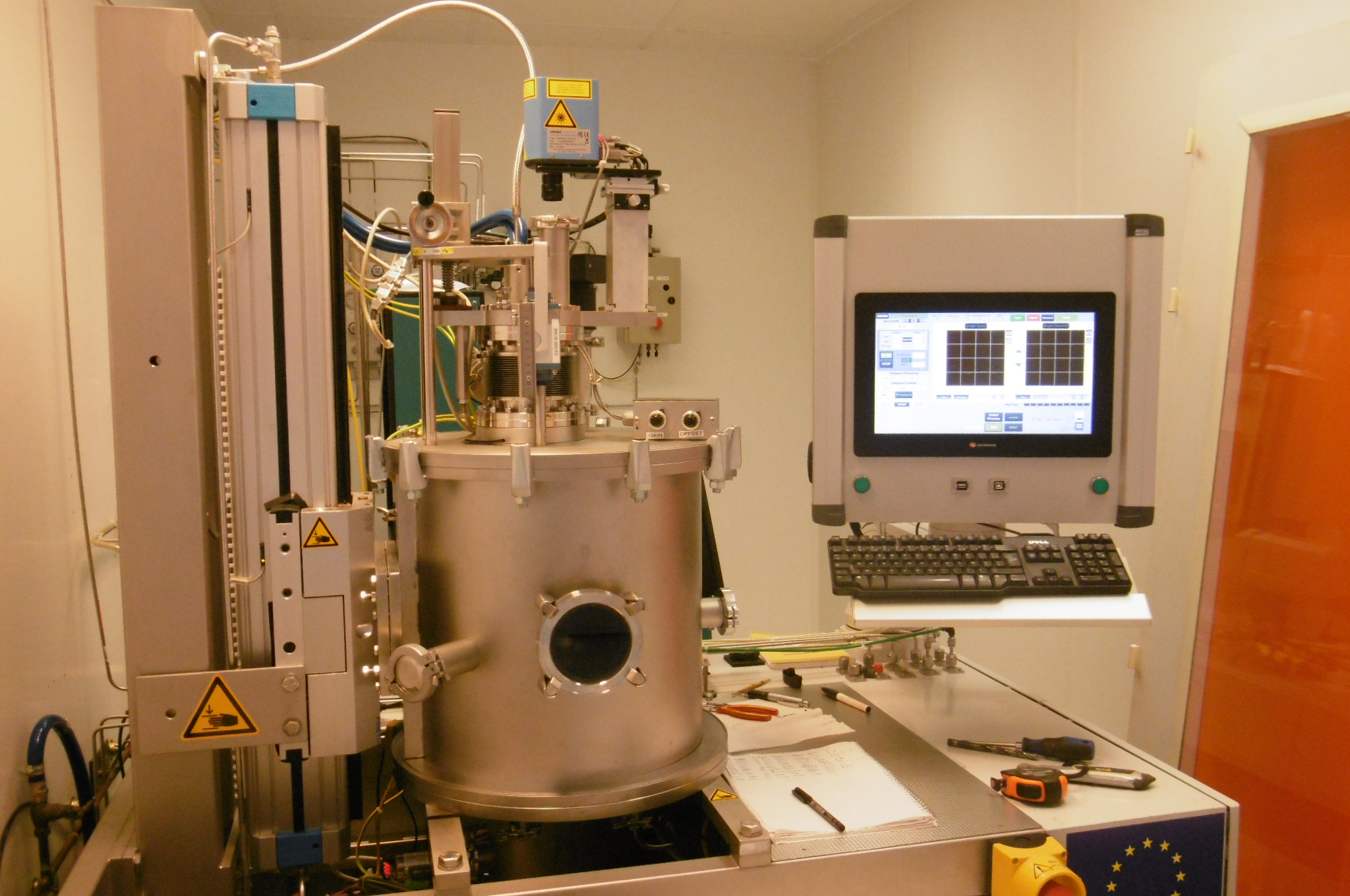

Dry etching

Plasma cleaner Plasmafab ETA Electrotech (FOTON-INSA)

Gas : O2

Cleaning of remaining resists

Features :

- primary vacuum (10-3 mbar)

Wet etching

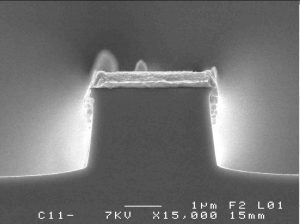

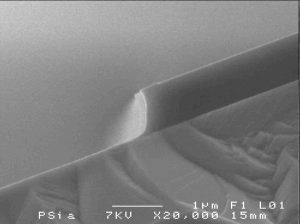

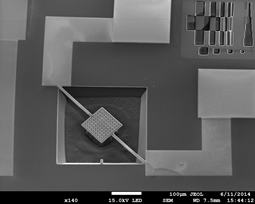

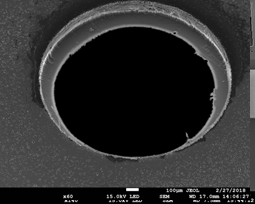

►Etching examples