►Know-how

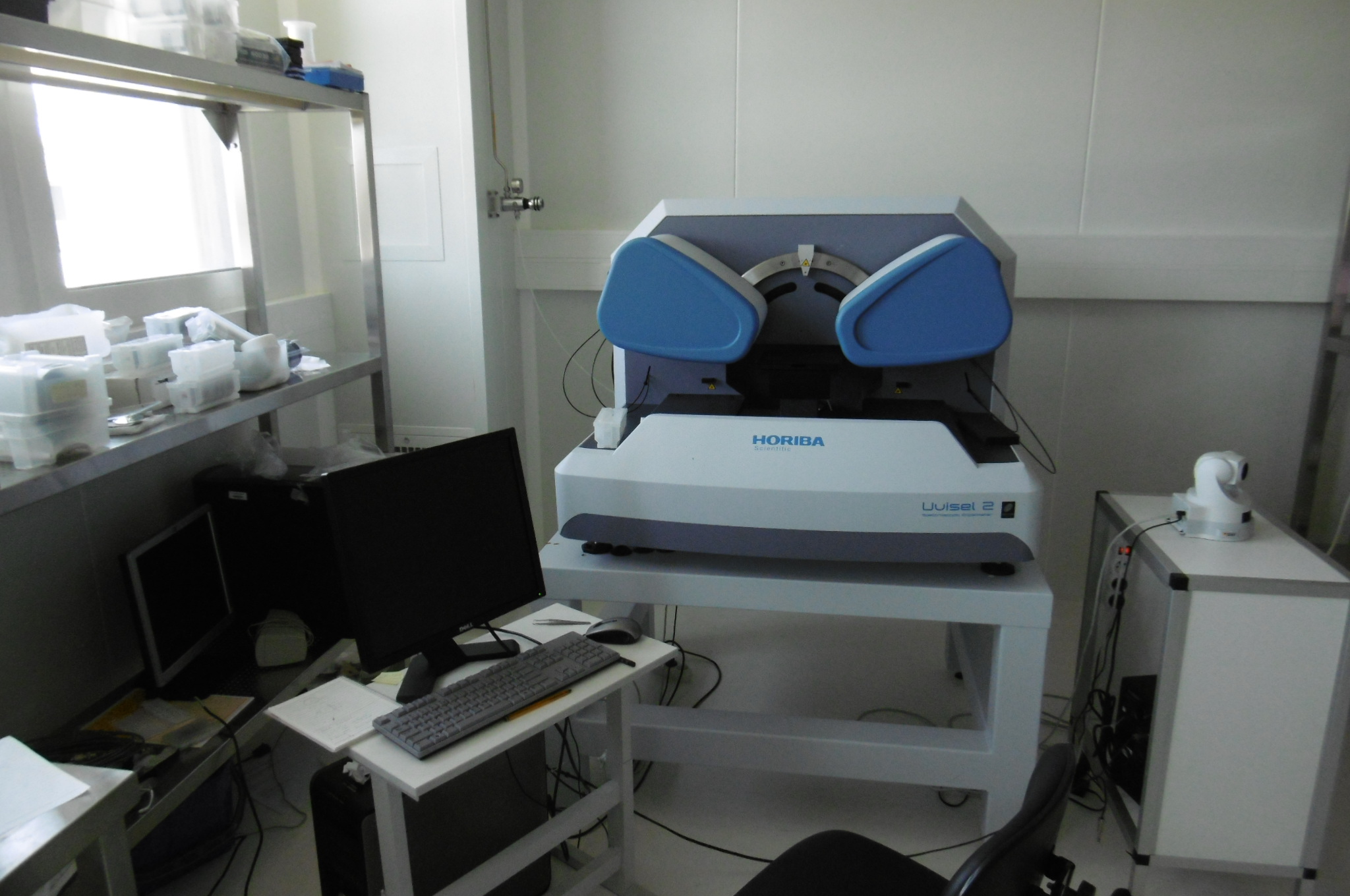

The Nano-Rennes platform has a set of tools in clean rooms that allow ongoing control and characterization of processes. These tools fall into two categories:

- Control tools

- Metrology tools

►Description of clean rooms characterisation equipment

Control tools

4 Olympus microscopes (IETR-GM, FOTON-INSA)

- Magnification from ×50 to ×200

- UV filter

- Camera

Metrology tools

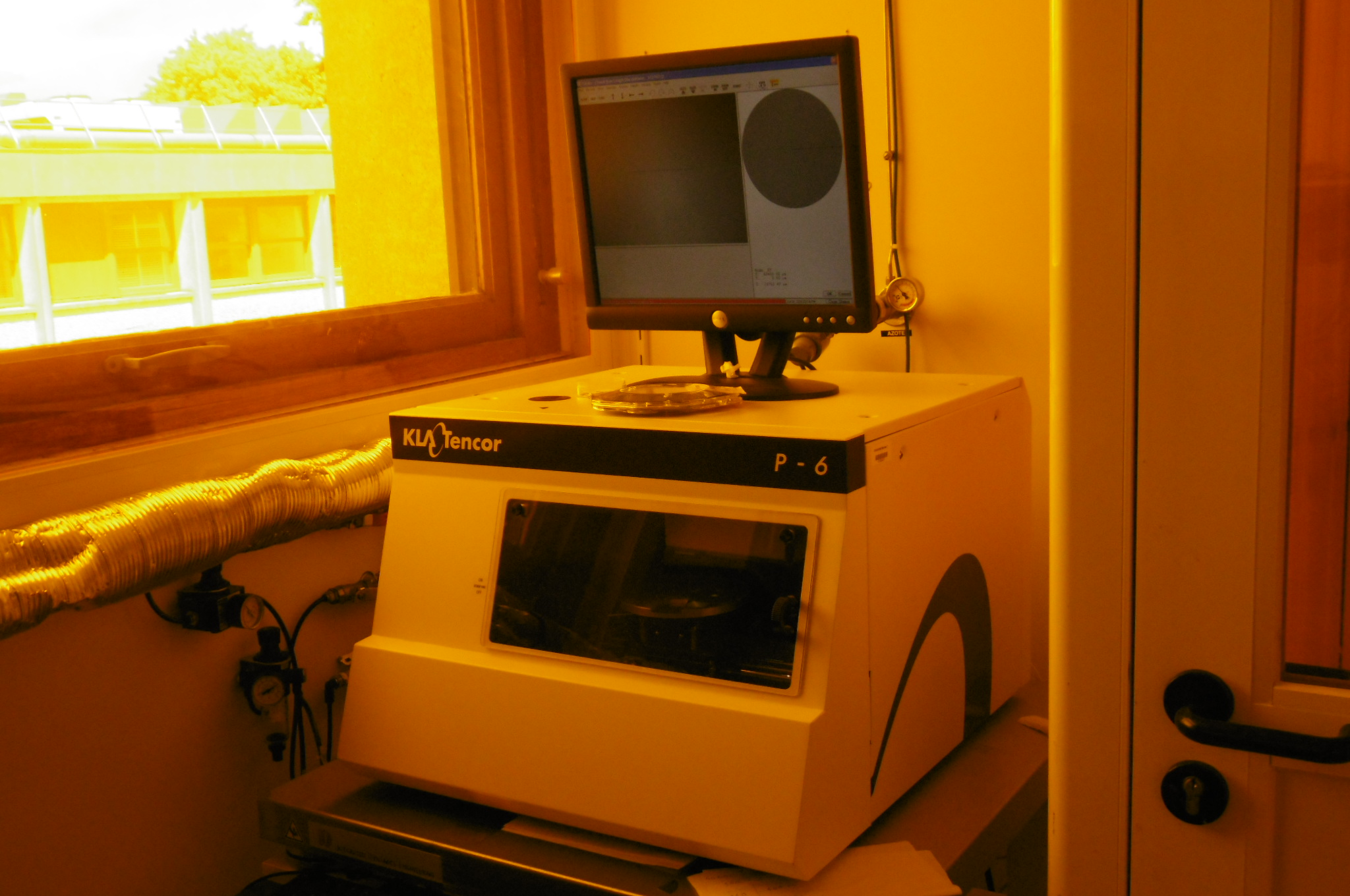

2 Tencor and Taylor-Hobson stylos profilometers (IETR-GM, FOTON-INSA)

- Accuracy: 0,1 %, tip of R=2.5 µm

- Max. length sweep: 10 cm

- Scanning speed: from 2 to 200 µm/s

- Samples dimensions: 4 inches

- Samples height: up to 17,5 mm

- Contact force: adjustable from 1 to 100 mg

- Operating height from some nm to 3 mm

- Stess measurements

4 pikes Jipelec measurements (IETR-GM)

- Resistivity characterisation

- Doping control (Si sector)

3 under pike measuring stations (ITER-GM, FOTON-INSA)

Tektronik 370A: measurements I(V) (AC, DC), low and high voltage (2kV)

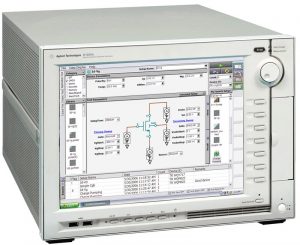

Agilent 1500 : measurement I(V), C(V), pulse, max voltage 40V

- Characteristics plotter coupled to an under pike measurement system

- Micrometric displacement

- Visualisation by microscope or binocular

Notes :

- A measuring station reserved for training

- Component characteristics, square resistance measurement (TLM method), resistivity measurement

►Examples of achievements

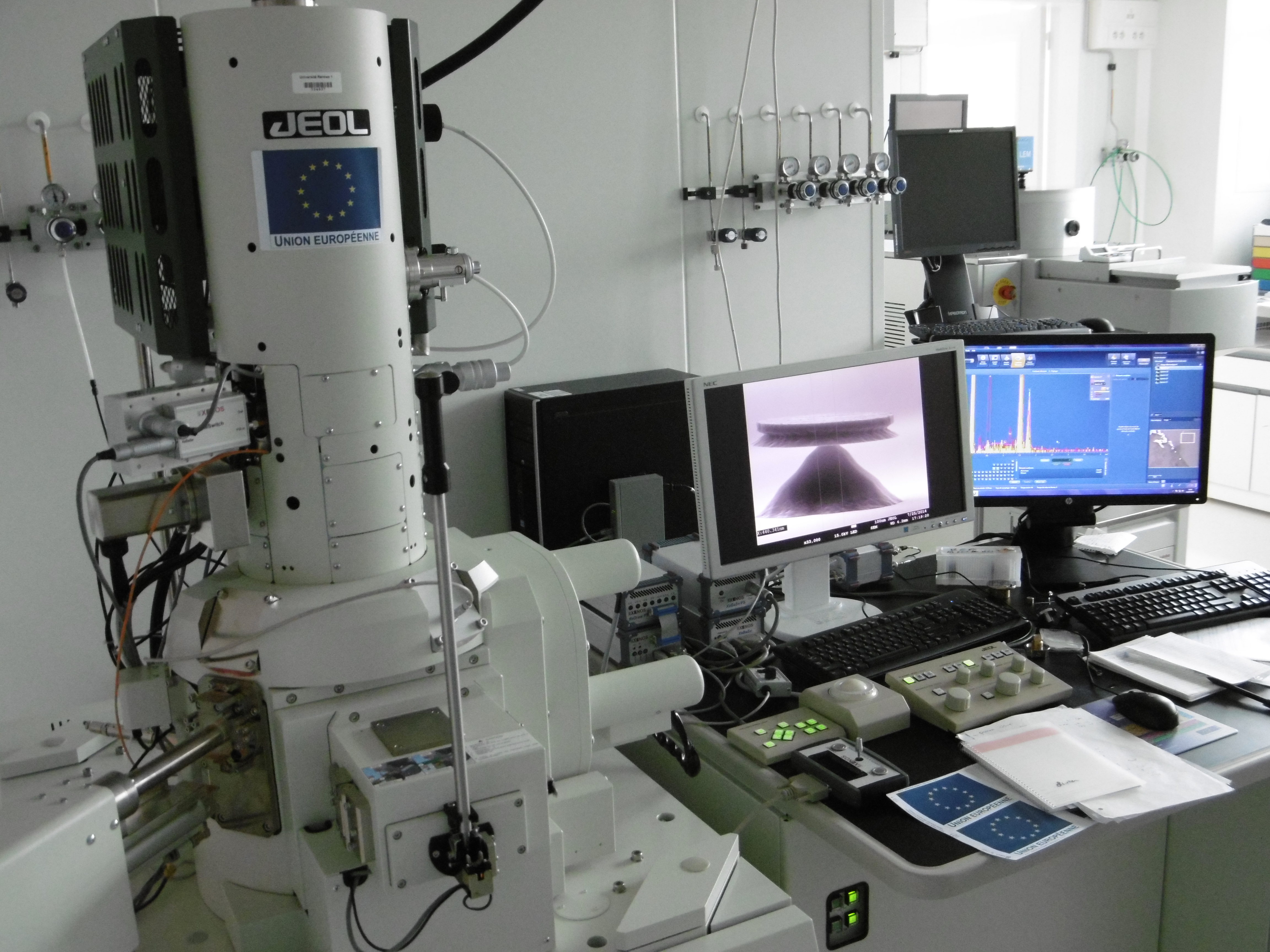

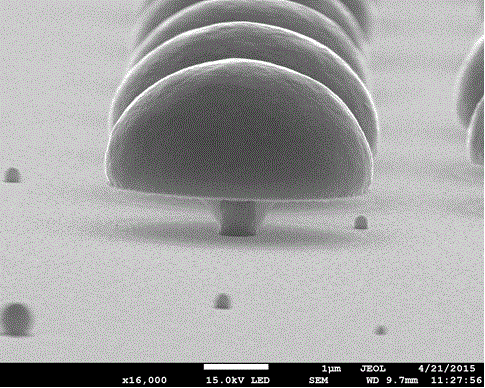

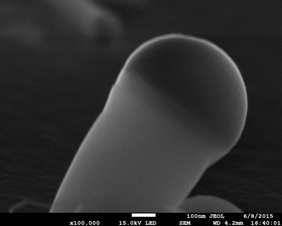

Sanning Electron Microscopy (SEM) shots